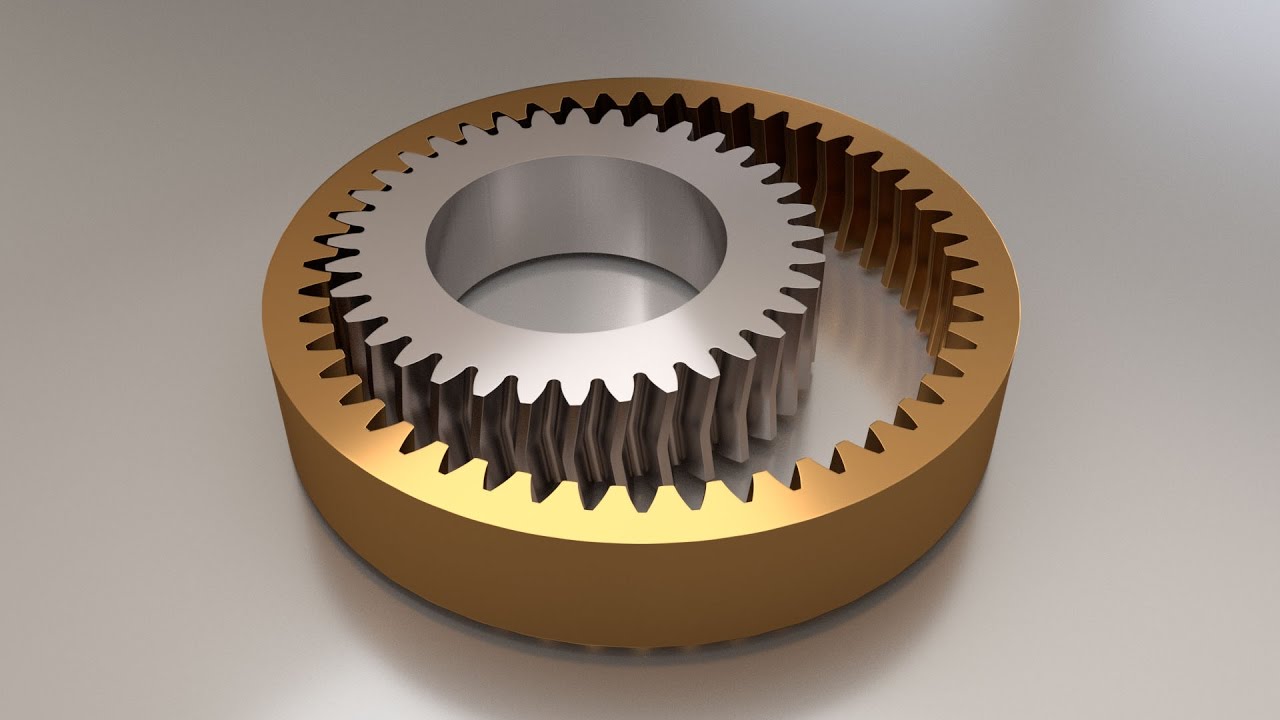

Internal gear is usually a gear using its teeth cut in the internal surface area of a cylinder and meshes with spur gears.

In its manufacturing, due to its shape, the most common hobbing machine used in spur gear creation can’t be used. Generally it really is made out of gear shaper (or gear shaping machine) equipped with a pinion cutter. Recently, the efficiency of inner gear cutting offers been improved by a different procedure called skiving.

Due to the thinness of the ring, it is sometimes difficult to produce high precision. On the other hand, gear grinding to  improve precision grade is limited by the number of producers and their available grinding facilities resulting in very high cost.

improve precision grade is limited by the number of producers and their available grinding facilities resulting in very high cost.

Also, although it is generally too expensive to create helical teeth internal gears, Ever-Power has made it possible to create them simply by adopting equipment that may cut them by simply making pinion cutters rather than needing helical guides.

Normally, internal gears can be utilized with the same module spur gears, depending on the number of teeth combinations, nonetheless it is necessary to notice the possibilities of getting involute, trochoid or trimming interferences. For using Ever-Power standard share gears, please seek advice from the PDF formatted “Technical Details of Internal Gears” section for usable quantity of teeth combinations.

Internal gears tend to be used in applications involving planetary gear drives and gear couplings. There are three main types of planetary gear mechanisms: planetary, solar and star types. Based on the type and the pattern of which shafts act as input and output, many variations of rate tranny ratios and rotational directions are created.